Project requirements

Our client (Anmar), an international installation company, requested electrical design services for a new pig iron caster at a steel processing facility in Ontario, Canada. The scope was to deliver design support services for the new addition of the plant, which included an electrical room, warehouse, and new conveyor equipment. As multidisciplinary cooperation was involved, it became critical to coordinate the electrical part of the design with other disciplines in a 3D modelling environment.

Solutions

From the very start of the project until its completion in more than a year, Engineering Solutions provided the following services for the project:

- Complex power system study for normal power & emergency power scenarios;

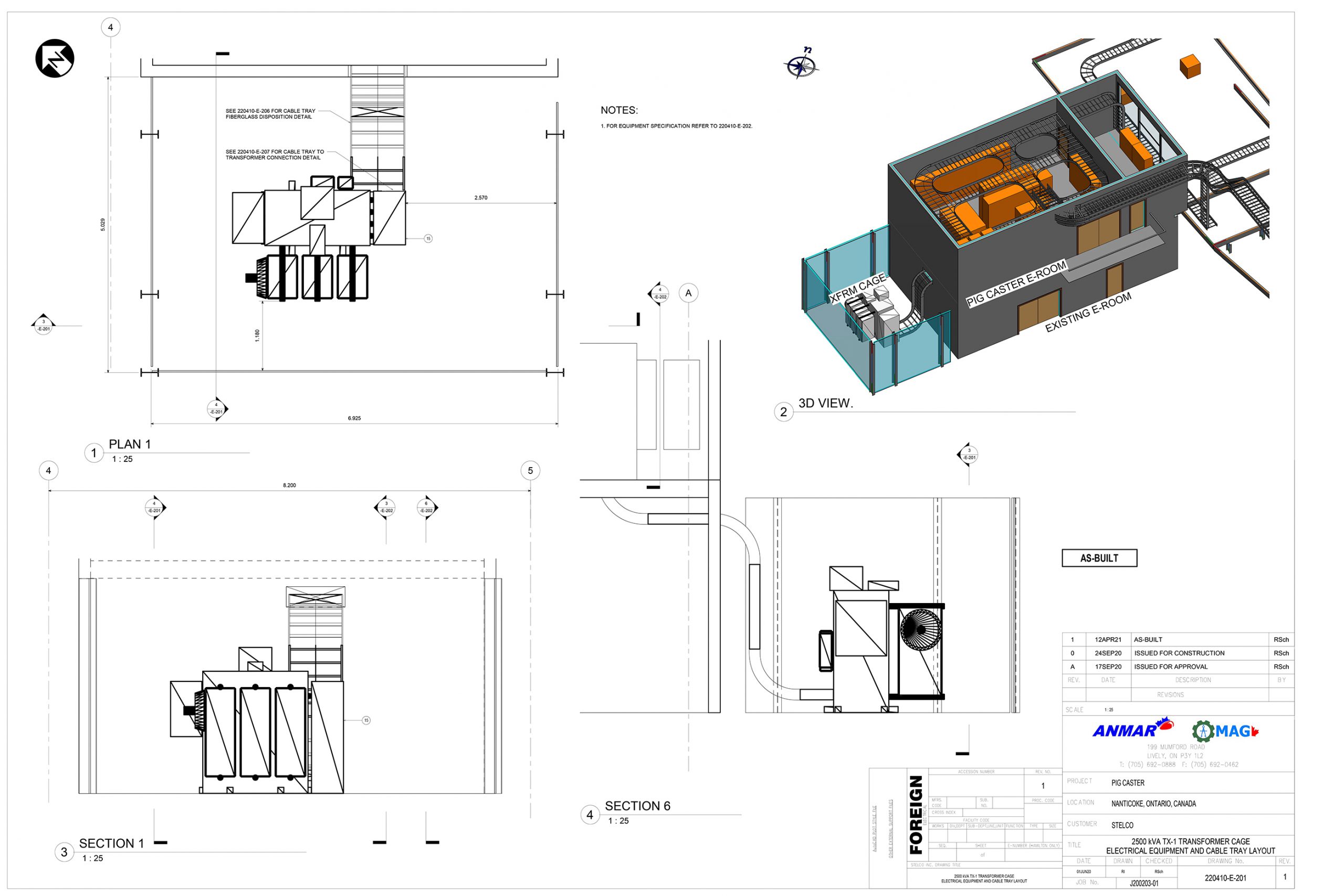

- Electrical room layout;

- Lighting design and simulations;

- Electrical drafting and BIM modelling services.

Project outcome

The pig iron caster was successfully commissioned and has the capability of casting up to one million tons of pig iron per year. The addition of the pig iron caster will allow the steel facility to fully capitalize on increased capacity resulting from the recently completed blast furnace upgrade project.

Accurate design produced by Engineering Solutions helped the customer to avoid issues by helping coordinate all disciplines, deliver accurate calculations and electrical designs for the steel facility.